Condition Monitoring

Check our prices

Real-time condition monitoring that deploys in minutes

Save Time

Replace manual walkarounds with real-time monitoring of vibration, temperature, and power across mission-critical equipment.

Reduce Downtime

Identify issues early and avoid unplanned outages to reduce downtime and improve maintenance efficiency.

Flexible deployment

Deploy wireless Samsara sensors for vibration and temperature in a matter of minutes and begin collecting data in easy-to-use cloud dashboards.

How It Works

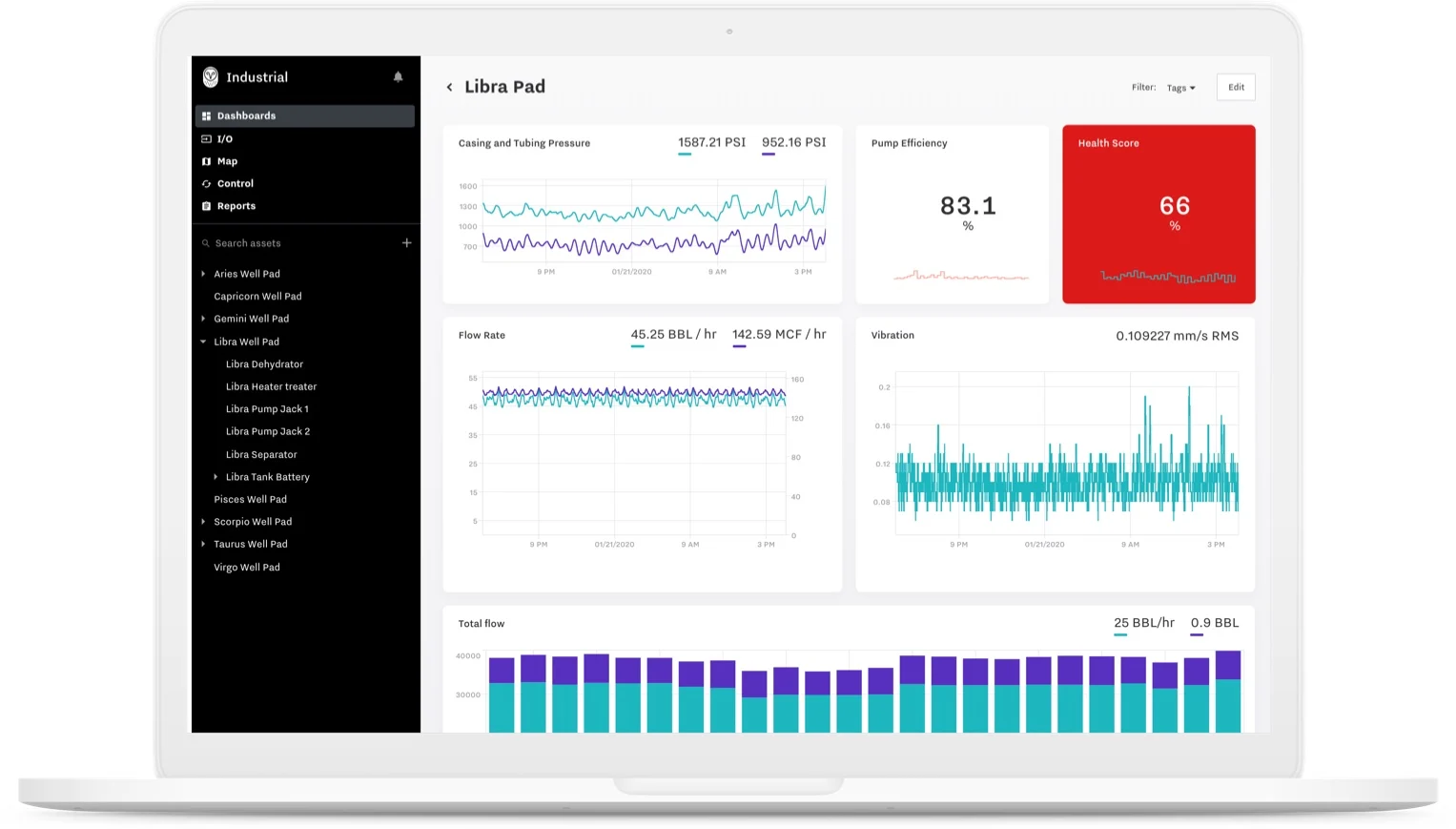

Unified asset health dashboard

Monitor critical equipment across plants or remote sites on one screen, with real-time visibility and alerts on the health of each machine.

Plan maintenance based on actual performance

Get a complete history of machine health by tracking vibration, temperature and power consumption data continuously

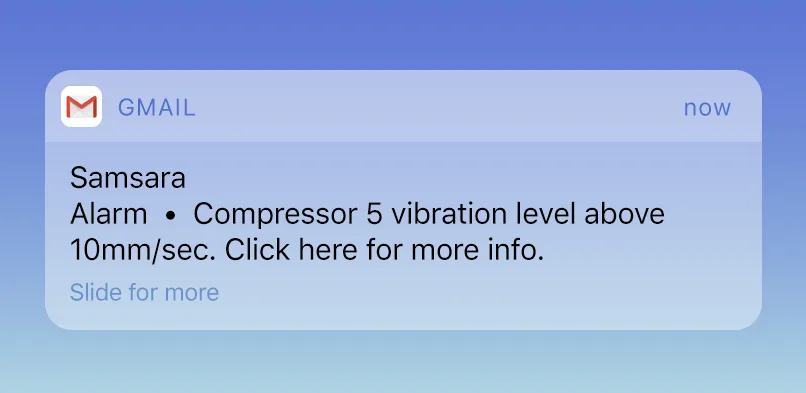

Catch issues before they happen

Get instant alerts over email and SMS so maintenance teams can stay on top of problems, and prevent expensive unplanned downtime

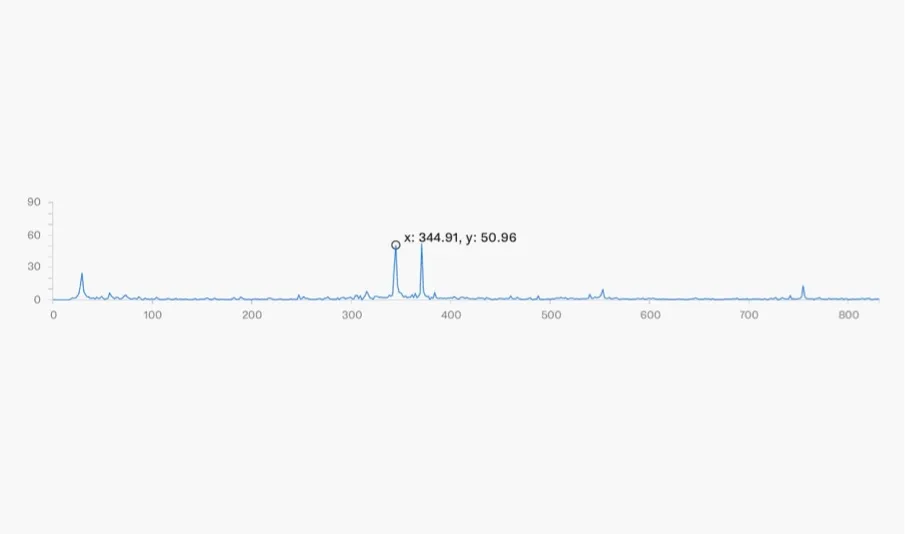

Diagnose machine faults

Use advanced analysis tools like FFT (Fast Fourier Transform) to understand critical details and identify root causes for potential failures

Identify costly demand spikes

With fine-grained energy consumption and power factor visualizations, operators can identify inefficiencies and reduce demand charges.

Installs in minutes

Industrial gateways include embedded cellular and pre-provisioned service for easy data transmission.

Samsara’s wireless sensors mount directly onto machines, no need to run conduits or wiring

IP67-rated sensors protect against water and dust in harsh industrial environments

Minimal-configuration - no servers or IT setup required