DTC code P0455: Large EVAP system leak

P0455 indicates a large leak in the evaporative emission control (EVAP) system, which captures fuel vapors from the gas tank and prevents them from escaping. When there’s a large leak, the system cannot maintain proper pressure, allowing fuel vapors to escape. The most common cause is a loose or damaged gas cap, leading to increased emissions, reduced fuel efficiency, and failed smog tests.

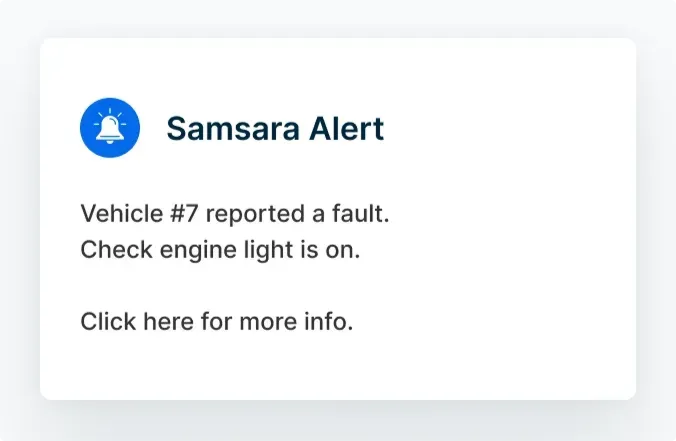

Samsara’s Fleet Maintenance solution can help you stay ahead of P0455 and other maintenance issues. Want to learn more? Share your email to get started.

Get StartedWhat is a DTC code?

A DTC code (Diagnostic Trouble Code) is a standardized code used to identify issues with key vehicle components like the engine, transmission, or emissions system. DTC codes are part of a vehicle’s OBD (On-Board Diagnostics) system and are commonly triggered when the check engine light turns on.

Typically, DTC codes typically begin with a letter (like P for powertrain) followed by four digits (such as P0128). For heavy-duty vehicles, DTC codes are typically specified under the J1939 protocol, and each code contains two parts: the Suspect Parameter Number (SPN), which identifies the specific component or system involved, and the Failure Mode Identifier (FMI), which indicates the type of problem detected.

By using DTC codes, fleets can streamline vehicle maintenance, helping to minimize repair costs, reduce downtime, and improve vehicle health.

What is OBD (On-Board Diagnostics)?

On-Board Diagnostics (OBD) is a system built into most modern vehicles that monitors engine performance, emissions, and other critical systems. Most vehicles use OBD-II, the second-generation standard, which continuously tracks key systems and generates diagnostic trouble codes (DTCs) when issues arise. OBD helps fleet managers, mechanics, and vehicle owners detect problems early, maintain engine health, improve fuel efficiency, and stay compliant with emissions regulations.

What are the symptoms of a P0455 code?

A P0455 code indicates a large leak in the vehicle’s EVAP (Evaporative Emission Control) system. Key symptoms include:

The check engine light is illuminated.

A noticeable fuel odor may be present near the gas tank or vehicle.

Failed emissions or smog tests may occur.

Minor drivability issues, such as rough idling or hesitation, may appear in some cases.

The EVAP system may be unable to maintain proper pressure, affecting overall emissions control.

What are the causes of a P0455 code?

The P0455 code is commonly triggered by large leaks in the EVAP system, which prevent fuel vapors from being contained. Common causes include:

Loose, missing, or damaged gas cap (most common)

Cracked, disconnected, or damaged EVAP hoses

Faulty purge or vent valves

Damaged fuel tank or other EVAP system components

Wiring or connector issues related to the EVAP system

How serious is the P0455 code?

The P0455 code is considered serious because it indicates a large leak in the vehicle’s EVAP system, which prevents fuel vapors from being properly contained.

If the leak is not addressed, it can cause a strong fuel odor, increased emissions, and failed emissions tests or smog tests.

Driving with a large EVAP leak can create a fire hazard due to fuel vapors.

Ignoring the code may worsen emissions, reduce fuel efficiency, and allow vapors to escape.

Can I still drive my vehicle with a P0455 code?

No, you should not continue driving with a P0455 code. While the engine may still run, a large EVAP system leak allows significant fuel vapors to escape, which poses a serious fire and safety risk. Other concerns include:

Increased emissions and fuel consumption.

Higher chance of failing emissions tests or smog inspections.

Risk of the EVAP leak worsening over time, leading to further repairs.

How do I fix a P0455 code?

To fix P0455, address the large leak in the EVAP system. Common steps include:

Tighten or replace a loose or missing gas cap.

Inspect and repair cracked or disconnected EVAP hoses.

Test and replace faulty purge or vent valves.

Replace damaged EVAP components, such as the fuel tank or canister.

Check related wiring and connectors for damage and repair as needed.

Clear the code and test drive to ensure the issue is resolved.

What is fleet maintenance?

Fleet maintenance encompasses all activities that keep your vehicles operational and in good repair, including preventive maintenance, regular maintenance, and addressing breakdowns to control maintenance costs.

What is fleet management?

Fleet management involves overseeing all aspects of your vehicle fleet, from acquisition to disposal, including maintenance schedules, tracking real-time data via telematics, and optimizing operations for overall cost savings.

How can a modern fleet maintenance solution help improve efficiency?

Modern fleet maintenance technology like Samsara leverages AI to help fleets take control on their maintenance operations. By harnessing the power of your fleet's data, you can save time and boost utilization, track costs for deeper insights, and consolidate systems for streamlined workflows—driving efficiency, savings, and a resilient, profitable fleet. Some benefits include:

Save time and increase utilization: Accelerate work order creation with automated data, reduce repeat shop visits with smart suggestions, and plan maintenance proactively with a unified view.

Track costs and identify issues: Analyze cost trends with reporting and identify problem areas with historical data.

Consolidate systems and processes: Integrate maintenance directly in Samsara for simplified and safe driver assignment and route creation, and use native integrations and APIs for critical maintenance operations.

Use AI to reduce manual work: Solve issues efficiently with Samsara’s AI, using smart alerts and tools to surface fault codes, generate action steps, analyze invoices, and reduce manual paperwork.

![Platform WR-FY26 - Animated Image - Centarus [US]](https://images.ctfassets.net/bx9krvy0u3sx/5xngcjfrqRSfiEFZevzlif/969f811d73f9e54371a9b65d54f6c9f4/certarus-image.png?w=2160&h=1886&fm=webp&q=80)